Cummins Isx Fuel Actuator Problems

Paragraph 1:

Cummins ISX engines are widely used in commercial vehicles for their reliability and power. However, this does not mean that they are immune to problems. One of the common issues that can affect these engines is fuel actuator problems. Fuel actuators are responsible for controlling the amount of fuel that is injected into the engine. If they become faulty, it can cause a number of issues that can lead to decreased performance and even engine failure. In this article, we will explore the causes and symptoms of Cummins ISX fuel actuator problems, and how they can be fixed.

Paragraph 2:

What is a Fuel Actuator and What Does it Do?

A fuel actuator is a device used in diesel engines to control the amount of fuel that is injected into the combustion chamber. It is an essential component of the fuel system, and is responsible for regulating the fuel pressure and flow rate. Without this device, the engine would not be able to properly regulate the fuel-air mixture and would not be able to achieve optimal performance.

Paragraph 3:

What are the Causes of Cummins ISX Fuel Actuator Problems?

There are a number of potential causes of fuel actuator problems in Cummins ISX engines. The most common cause is a malfunctioning or faulty fuel actuator. This can be caused by a number of things, including a faulty wiring harness, a faulty or broken sensor, or a worn out or damaged actuator. In some cases, the problem may be caused by a faulty ECM (engine control module).

Paragraph 4:

What are the Symptoms of Cummins ISX Fuel Actuator Problems?

When a Cummins ISX fuel actuator is not functioning properly, it can cause a number of symptoms. These symptoms may include reduced fuel economy, rough idling, misfiring, stalling, and excessive smoke. The engine may also produce a knocking or rattling sound, and the power output may be reduced.

Paragraph 5:

How Can Cummins ISX Fuel Actuator Problems Be Fixed?

The best way to fix Cummins ISX fuel actuator problems is to replace the faulty part. This should be done by a qualified mechanic, as the process requires specialized tools and knowledge. In some cases, it may also be necessary to replace the wiring harness, sensors, or ECM.

Paragraph 6:

In some cases, Cummins ISX fuel actuator problems can be prevented with regular maintenance. This includes checking the fuel system for leaks, inspecting the wiring harnesses, and replacing any worn or damaged parts. In addition, the fuel filter should be changed regularly, as this will help to ensure that any dirt or debris is removed from the fuel system.

Paragraph 7:

In conclusion, Cummins ISX fuel actuator problems can be caused by a number of things, including faulty wiring, worn or damaged components, and a malfunctioning ECM. These problems can cause a number of symptoms, such as reduced fuel economy, rough idling, and engine stalling. The best way to fix these problems is to replace the faulty part, and regular maintenance can help to prevent them from occurring in the first place.

Where is the fuel shut off switch on a cummins 8.3 liter 215, 1999 ISC

Infamous Cummins ISX Fuel Pump FAILURE - YouTube

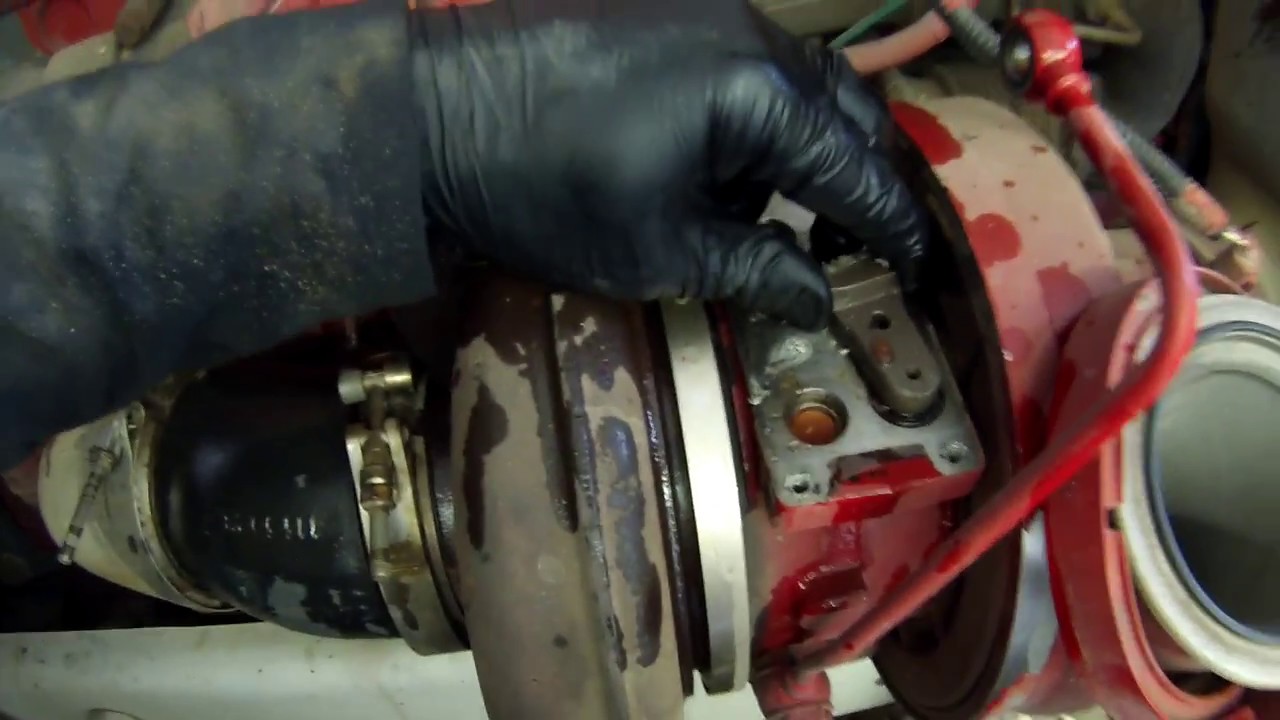

How to check if Turbo and/or Actuator is bad on Cummins ISX - YouTube