Transmission Molded Leadframe Extended Coverage

Transmission Molded Leadframe (TML) technology is an advanced method of producing plastic-molded leadframes that is used in the manufacturing of semiconductor packages. The leadframe is a critical part of the semiconductor package that connects the external pins of the package to the internal die. It is also used as a platform for other components, such as heat spreaders, solder balls, and contact fingers. TML technology enables the leadframe to be molded to a package shape that provides a larger surface area for components and improved electrical performance.

Benefits of Transmission Molded Leadframe

Transmission Molded Leadframe technology offers a number of benefits to semiconductor manufacturers. One of the primary benefits is the ability to extend the coverage area of the leadframe. This allows for more components to be placed on the leadframe, improving package density and overall performance. In addition, the increased coverage area allows for improved connectivity between the die and the external pins of the package. This improved connectivity can result in improved electrical performance of the package.

Improved Reliability and Cost Reduction

Another benefit of TML technology is improved reliability. The extended coverage area of the leadframe helps to protect the components and ensure a reliable electrical connection between the die and the external pins of the package. This can help to reduce the cost of manufacturing by reducing the number of defective packages. Additionally, the improved electrical performance of the package can help to reduce the power consumption of the device, resulting in further cost savings.

Enhanced Heat Dissipation

The extended coverage area of the leadframe also helps to improve the heat dissipation of the package. This can be beneficial for high-power applications, as it can help to reduce power consumption and improve the overall efficiency of the device. In addition, the improved heat dissipation can help to extend the lifetime of the device, further reducing the cost of manufacturing.

Improved Design Flexibility

TML technology also offers improved design flexibility. The extended coverage area of the leadframe allows for a variety of different component shapes and sizes to be placed on the leadframe. This can help to reduce the overall size of the package, as well as reduce the complexity of the design. This can help to reduce the cost of manufacturing and improve the overall performance of the device.

Improved Yields

Finally, TML technology can also offer improved yields. The extended coverage area of the leadframe allows for more components to be placed on the leadframe, resulting in improved yields. This can help to reduce the cost of manufacturing and improve the overall efficiency of the device.

In conclusion, Transmission Molded Leadframe technology offers a number of benefits to semiconductor manufacturers. It can help to extend the coverage area of the leadframe, resulting in improved electrical performance, improved reliability, improved heat dissipation, improved design flexibility, and improved yields. As such, it is an invaluable tool for semiconductor manufacturers looking to reduce the cost of manufacturing and improve the performance of their devices.

Transmission Molded Leadframe Extended Coverage - Fordmasterx

Transmission Molded Leadframe Extended Coverage - Fordmasterx

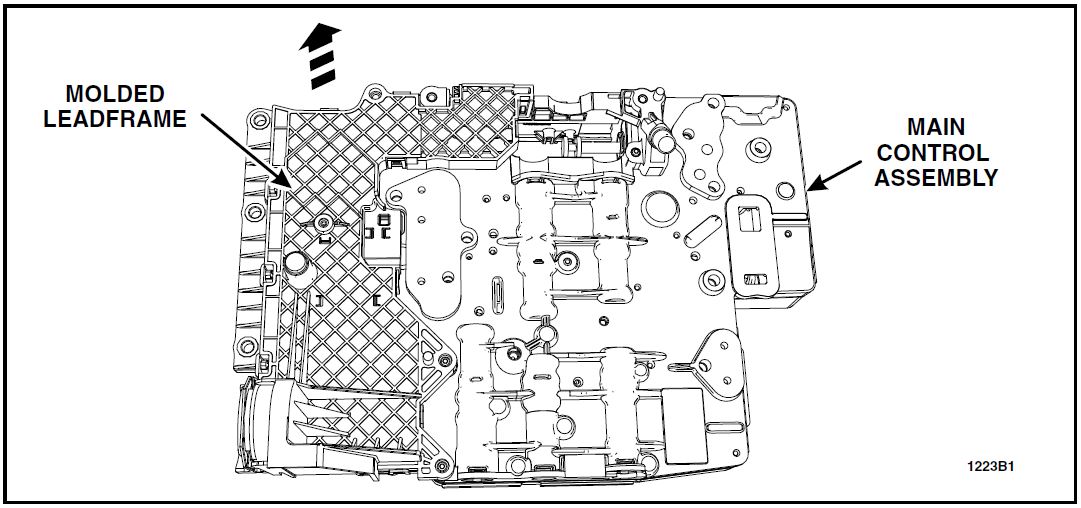

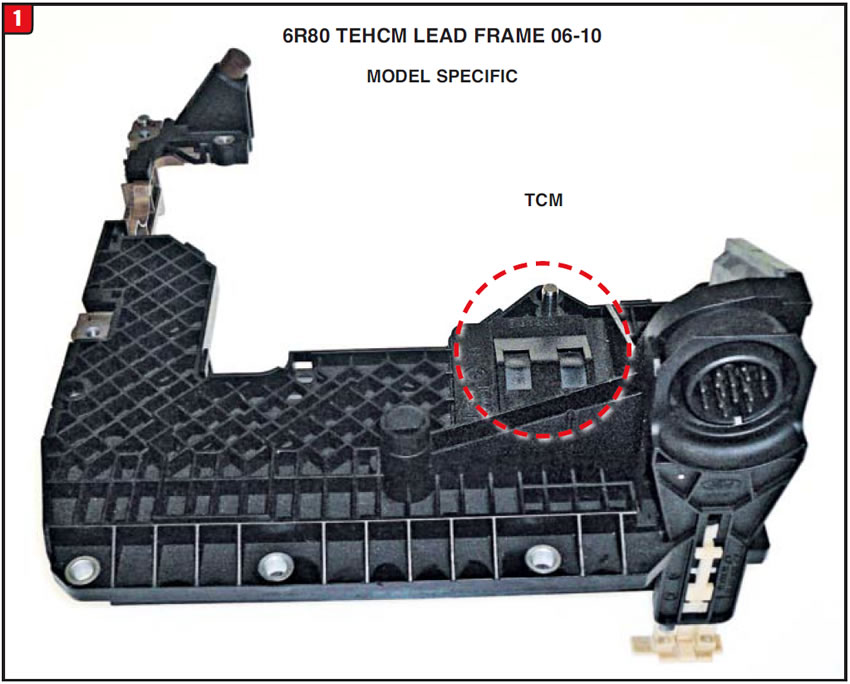

16N02 – Molded Leadframe Extended Coverage – 2011-2012 Ford & Lincoln